Overview of the sealing performance of trigger sprayers

The sealing performance of trigger sprayers is a key factor in ensuring their normal use and preventing liquid leakage. The quality of sealing performance directly affects the efficiency and safety of the sprayer. The sealing structure design of the liquid storage and injection system inside the sprayer can prevent liquid leakage during transportation, storage or use. The sealing performance is not only related to the user experience, but also to the effective use of liquid, reducing waste and environmental pollution.

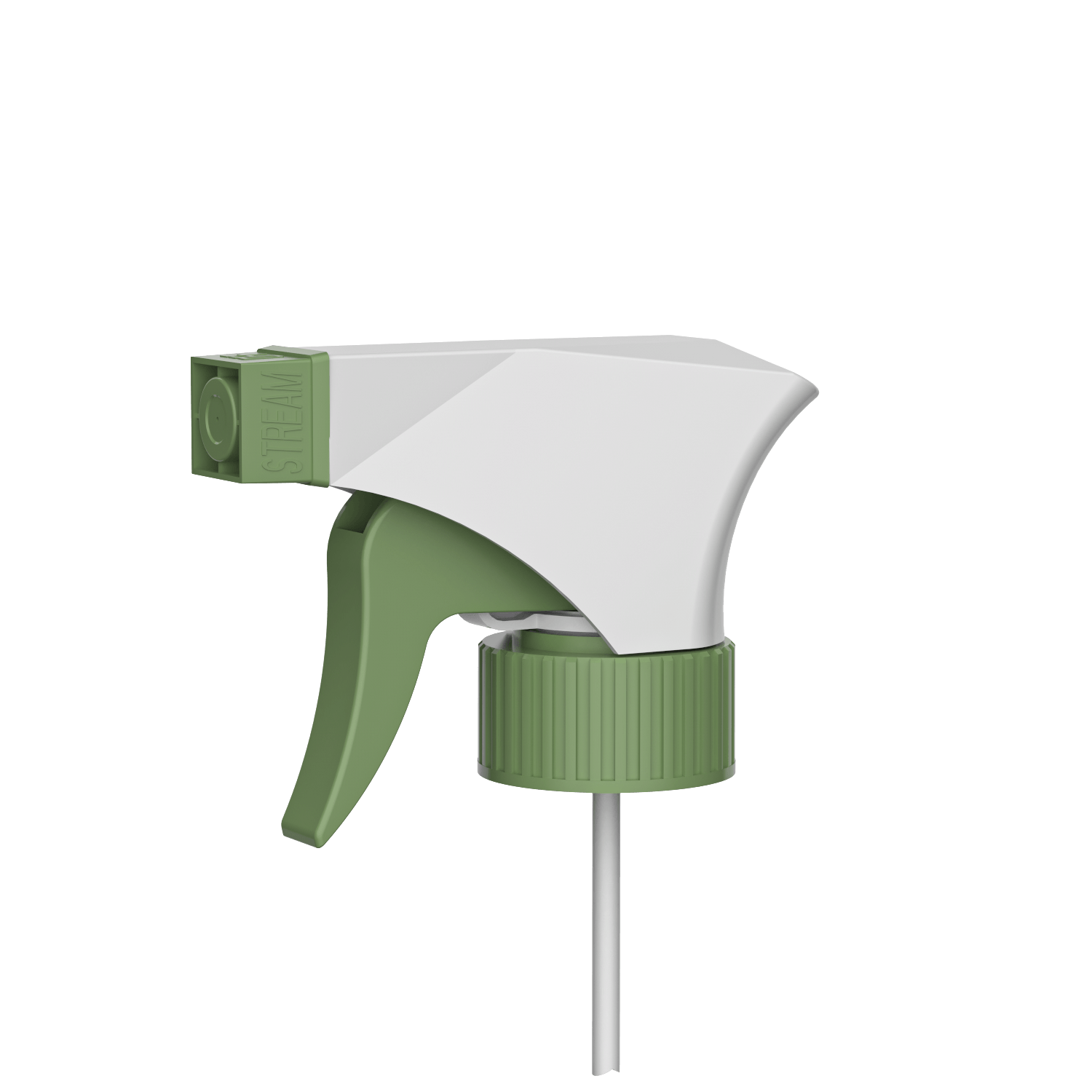

Composition of the sealing structure of the trigger sprayer

The sealing structure of the trigger sprayer usually includes a bottle cap seal, a nozzle seal and a pump body seal. The bottle cap seal is an important part of the connection between the bottle body and the sprayer body to ensure that the liquid does not leak from the interface. The nozzle seal prevents the spray port from backflowing and leaking, ensuring that the liquid is only sprayed from the nozzle during the spraying process. The pump body seal is responsible for the sealing of the liquid circulation in the pump to prevent the liquid from leaking to the outside of the pump body. These seals are generally made of rubber, silicone or other elastic materials to ensure good sealing effect and certain durability.

Design details to prevent liquid leakage

In the design of trigger sprayers, in order to prevent liquid leakage, common practices include multiple sealing designs, selection of sealing ring materials, and tight integration of interface parts. Multiple sealing designs enhance the sealing effect by setting multiple sealing layers. Even if one layer is loose, other layers can still prevent liquid leakage. The material selection of the sealing ring needs to take into account elasticity, corrosion resistance and temperature resistance, and adapt to the physical and chemical properties of different types of liquids. In addition, the thread tightness and matching tolerance of each interface of the sprayer are also important factors to prevent leakage. Reasonable thread design can ensure that the connection is firm and easy to load and unload.

Common factors affecting sealing performance

The sealing performance of the trigger sprayer is affected by many factors, among which material aging, use environment and maintenance status are the main factors. After long-term use, the sealing material may age due to oxidation, ultraviolet radiation or chemical corrosion, resulting in weakened elasticity and cracks, thereby affecting the sealing effect. Extreme temperatures or strong acid and alkali liquids in the use environment may also accelerate the damage of the seal. In addition, improper installation or lack of daily maintenance, such as failure to regularly check the sealing ring or failure to replace wear parts in time, will also reduce the sealing performance and increase the risk of liquid leakage.

How to detect the sealing performance of the trigger sprayer

The sealing performance of the trigger sprayer can be detected in two ways: static and dynamic. Static detection generally observes whether there is leakage in the sprayer filled with liquid in a static state, including the interface and around the nozzle. Dynamic detection is to observe whether there is liquid dripping or abnormal spraying in the spraying and closing states during the use of the sprayer. In addition, the pressure test method can also be used to increase the internal pressure to detect the pressure bearing capacity and sealing effect of the seal. For manufacturers, sealing performance testing is an important part of quality control to ensure that the product meets the design standards.

Maintenance method for the sealing performance of the trigger sprayer

In order to maintain the sealing performance of the trigger sprayer, users should pay attention to regularly check the status of the seal and promptly detect problems such as cracks, deformation or hardening. Replace the sealing ring when necessary to prevent liquid leakage due to aging of the seal. Avoid exposing the sprayer to extreme environments such as high temperature, strong direct sunlight or corrosive liquids when using it. When cleaning the sprayer, avoid using strong solvents or mechanical wiping of the sealing part to avoid damaging the sealing material. In addition, ensure that the bottle cap is tightened during storage to prevent liquid from flowing out due to poor sealing.

The impact of different liquid types on sealing performance

Trigger sprayers are often used to spray a variety of liquids, such as water-soluble detergents, oil-based lubricants or chemical pesticides. The physical and chemical properties of different liquids have different effects on seals. Water-soluble liquids generally have less erosion on sealing materials, but liquids with high acidity or alkalinity or containing organic solvents may accelerate the aging of the seal ring and shorten its service life. Therefore, it is particularly important to choose suitable sealing materials for different liquids. For example, chemically resistant fluororubber seals are suitable for certain special liquids. Understanding the characteristics of the liquid and selecting a matching sealing system are the key to ensuring the sealing performance of the sprayer and preventing liquid leakage.

Industry standards and testing specifications for the sealing performance of trigger sprayers

The industry has corresponding standards and testing specifications for the sealing performance of trigger sprayers to ensure that the product meets the basic requirements in terms of safety and practicality. It usually covers leakage rate limits, pressure resistance, material compatibility and durability tests. The standard also includes simulation tests for environmental factors, such as temperature cycle tests and chemical corrosion tests, to verify the performance of seals in actual applications. Manufacturers should design and inspect in accordance with relevant standards and obtain certification from third-party testing agencies to enhance users' confidence in the product's sealing performance.

Comparison of testing parameters for sealing performance of trigger sprayers

| Parameter | Description | Typical Range | Notes |

|---|---|---|---|

| Leakage Rate | Maximum allowable leakage volume | ≤ 0.1 ml/24h | Measured under standard pressure |

| Operating Pressure | Pressure during spray operation | 0.2 - 0.5 MPa | Varies by design and use case |

| Seal Material | Common sealing materials | Rubber, Silicone, FKM | Material chosen by chemical resistance |

| Temperature Range | Effective sealing temperature range | -20°C to 80°C | Depends on material |

| Durability | Estimated seal lifespan | 1 - 3 years | Depends on usage and environment |

.png)

English

English Español

Español русский

русский Français

Français italiano

italiano Deutsch

Deutsch