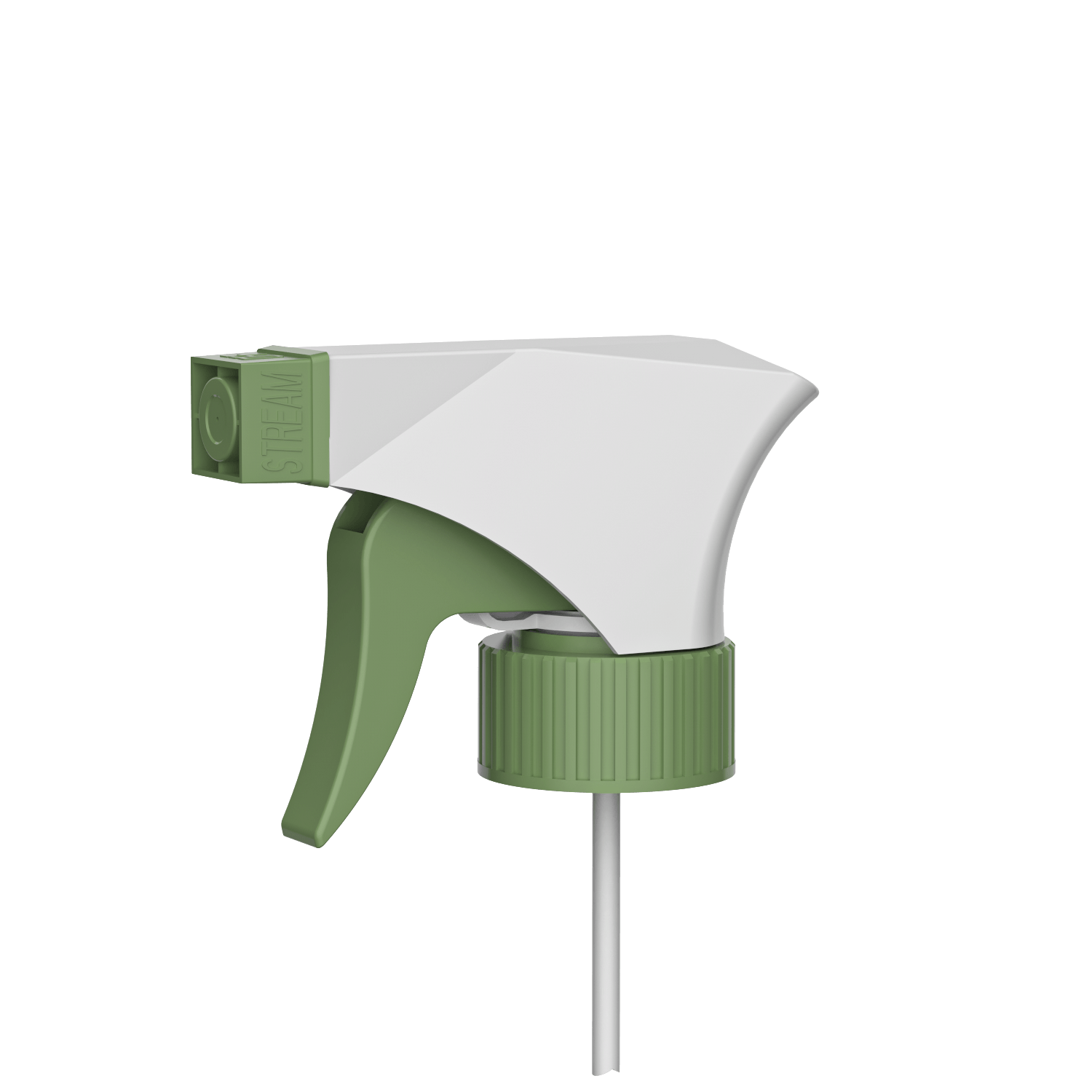

Overview of the production process of trigger sprayer

The production process of trigger sprayer involves multiple links, including injection molding, assembly, sealing treatment and injection performance debugging. The reasonable design and implementation of the production process is the basis for ensuring product quality and stable performance. During the injection molding process, the mold design and injection molding parameters are precisely controlled to ensure the consistency of the dimensions of each component and reduce deformation and defects. The assembly link requires strict process management to ensure the precise matching and tight integration of the components. The sealing treatment effectively prevents liquid leakage through the standardized operation of the sealing ring material and installation method. The final injection performance debugging ensures that the sprayer can achieve the designed injection pressure and spray effect.

The role of injection molding process in the production of trigger sprayer

The injection molding process is a key link in the manufacture of trigger sprayer. Its quality directly affects the dimensional accuracy and surface quality of product parts. By selecting suitable plastic materials and adjusting the temperature, pressure, cooling time and other parameters of the injection molding machine, defects such as shrinkage, warping and bubbles of parts can be reduced. In the mold design, attention is paid to the reasonable layout of the flow channel and the configuration of the exhaust system to ensure that the plastic melt evenly fills the mold cavity. Stable injection molding process can effectively control the dimensional tolerance of the product, provide a basis for subsequent assembly, and improve the overall product consistency.

Assembly process ensures product performance consistency

The assembly of the trigger sprayer includes the combination of multiple components, such as bottle caps, nozzles, trigger rods and sealing rings. The assembly process requires the use of automated or semi-automated equipment to improve assembly accuracy and reduce human errors. The matching tolerances of key components must be strictly controlled to ensure tight connections. During the assembly process, especially the installation of the sealing ring, accurate positioning is required to prevent leakage. The specification of assembly torque and sequence in the process flow ensures the stability of the product structure and the consistency of spray performance. Efficient assembly process can also improve production efficiency and reduce defective rate.

Establishment and implementation of quality control system

The quality control system is the core link to ensure the consistency and stable performance of trigger sprayer products. Manufacturers usually establish a complete quality management system from raw material procurement, production process control to finished product testing. Physical and chemical properties of raw materials are tested when they enter the factory to ensure that they meet standard requirements. Process control is implemented during the production process, and online detection equipment is used to monitor key parameters such as injection temperature, pressure and assembly size. The finished product undergoes functional testing, including injection pressure testing, sealing testing, and durability testing. Through full-process monitoring and data recording, quality traceability and continuous improvement are achieved.

Application of automated equipment in production

With the development of technology, automated equipment is widely used in the production of trigger sprayers. Automatic injection molding machines, robot assembly lines, and automatic testing equipment improve the accuracy and consistency of production. Automated equipment reduces the differences in manual operations and improves the repeatability and stability of products. The automatic detection system can quickly identify unqualified products and reduce the scrap rate. Automated production not only improves production efficiency, but also provides reliable guarantees for mass production, which helps to meet the market demand for high-quality products.

Process optimization and continuous improvement of trigger sprayers

In order to cope with changes in market demand and improve product quality, manufacturers continue to optimize their processes. By introducing advanced materials, improving mold design, optimizing injection molding parameters, and improving assembly processes, the stability of the production process and product performance are continuously improved. At the same time, companies focus on employee skill training and process knowledge updates to promote the improvement of management levels at production sites. By using quality data analysis and feedback mechanisms, process bottlenecks and potential problems can be discovered in a timely manner, corrective measures can be implemented, continuous improvement can be achieved, and stable product quality can be ensured.

Common quality problems and solutions in the production process

The quality problems that may occur in the production of trigger sprayers include part size deviation, poor sealing, uneven injection, etc. Size deviation is mostly caused by mold wear or unstable injection parameters, and molds need to be regularly inspected and injection molding machine parameters adjusted. Poor sealing is usually related to the quality of the sealing ring material or improper installation. It is recommended to use standard seals and strengthen assembly quality control. Uneven injection may be caused by pump body design defects or poor assembly, and the structural design needs to be optimized and the assembly process needs to be improved. Through systematic quality management and problem feedback, the defect rate can be effectively reduced.

Key parameters and control indicators of the production process of trigger sprayers

| Process Stage | Key Parameters | Control Range / Standard | Impact on Product Quality |

|---|---|---|---|

| Injection Molding | Temperature, pressure, cooling time | ±5°C temperature, stable pressure | Affects part dimensions and surface finish |

| Assembly | Torque, alignment, component fit | Specified torque range, ±0.1 mm fit tolerance | Influences sealing and spray performance |

| Sealing | Seal material hardness, placement | Hardness Shore A 50-70, correct positioning | Prevents leaks and ensures spray consistency |

| Functional Testing | Spray pressure, flow rate | Pressure 0.2 - 0.5 MPa, flow rate consistent | Confirms spray quality and reliability |

The direct impact of production process on product performance

Stable production process directly guarantees the stable performance of trigger sprayers. The size and surface quality of injection molded parts determine the accuracy of component matching, affecting the overall structural strength and sealing performance. High-quality assembly process ensures the good combination of various parts of the sprayer to avoid liquid leakage and uneven injection. The sealing process and performance testing process ensure that the product exhibits the expected spray effect and service life in actual use. The close connection and process control of each link are the basis for product consistency.

.png)

English

English Español

Español русский

русский Français

Français italiano

italiano Deutsch

Deutsch